7Mary3

Member-

Posts

3,146 -

Joined

-

Last visited

-

Days Won

4

7Mary3 last won the day on March 29 2021

7Mary3 had the most liked content!

Recent Profile Visitors

4,292 profile views

7Mary3's Achievements

493

Reputation

-

Automotive Hall of Fame inducts Bill Ford

7Mary3 replied to mackinaw's topic in Ford Motor Company Discussion Forum

Don't know if I agree with all of this, but it raises some points: https://247wallst.com/investing/2024/04/30/ford-needs-to-replace-chairman-revamp-board/ -

Reminds me of a story I heard about the Excursion: Supposedly it was discontinued only because Bill Ford Jr. was on a 'green' kick and didn't like the negative publicity large SUV's like the Hummer were getting at the time. The Sierra Club was calling it the 'Ford Valdez' after the tanker that sunk. Even though the sales of the Excursion never came close to the GM Suburbans I can't believe the vehicle wasn't profitable. Nonetheless, Ford probably should have offered a long wheelbase Expedition from the start. I had a buddy that really wanted an Excursion but could only find ones with the 5.3L or 6.0L Powerstroke. It was a good wagon with the 7.3L or V10, and everyone knew that......

-

As for the gas 650/750 air brakes, my hunch FWIW is that it ended up requiring some expensive engineering and Ford doesn't see enough demand to justify it. We use a lot of large single-axle dumps, but they are 33,000 GVW with a Cummins L9N and Allison 3000 series transmission. Don't even look at Fords for that application, GCW is too light.

-

Does it have anything to do with emissions? The 6.7L Powerstroke appears to be non-compliant for 2025 CARB. Since Ford has already started the 2025MY for the 650 and 750, the trucks are gas only now here in California. Diesels are not available in 2025 650's and 750's. Isn't Mass. a CARB state?

-

Interesting topic, but it is ironic that Ford will probably be the LEAST likely truck manufacturer to offer the B6.7 Gas. The engine is attracting considerable interest, particularly from the manufacturers currently offering the B6.7 Diesel. Freightliner has already confirmed to their dealers, International is likely, Isuzu/Chevy a strong possibility in their class 6/7 LCF, and Mack would be silly not to in their medium duty. Good thing for Ford is they should still maintain a substantial price advantage over those potential gasoline medium truck competitors.

-

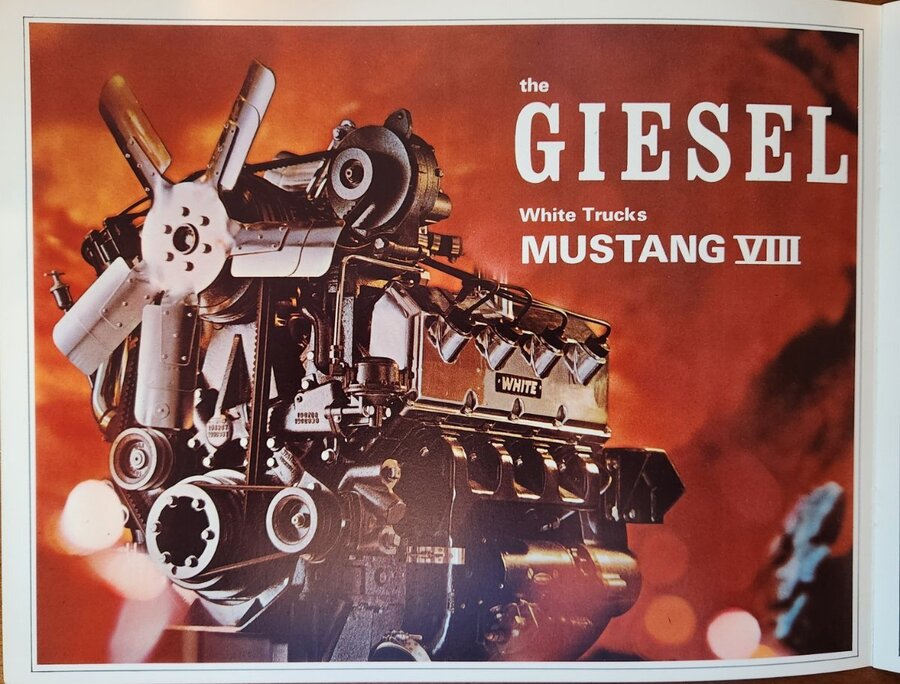

Oh yeah! That was done at the request of White Motors. When White spun off Diamond Reo in 1972 the Reo gas engines were included, that left White without a gasoline option. For a year or two White offered the GMC V-6's in some 4000 series trucks until they introduced the 'Giesel'. The 'Giesel' or 'Mustang VIII' as it was sometimes called was basically a Cummins 470 V-8 re-engineered into a gasoline engine. Lower compression pistons, spark plugs where the injectors were, a distributor and a 2bbl. Holley carburetor. I know few were made, but I never heard anything bad about the Giesel either. It was bound to be better than any of the small Cummins V-6 and V-8 diesels!

-

As I said, while the BEV mandate so to speak is being pushed faster than is technically and economically feasable at this point, I am nonetheles very much AMAZED at the rate of progess that has been made over just the last 5 years regarding BEV's. If it keeps up at the current pace near 100% of new light passenger vehicles may well indeed be BEV's by 2035. HEV's may represent something of a temporary stop-gap or bridge on the road to electrification, but I don't think they should be viewed as any sort of permanent solution. But in the end no one really believes we can give up ICE's by tomorrow anyway.

-

Sadly the French and Italian masters of the ruins of Chrysler Corporation seem very content to let the Ram HD's wither on the vine. From what I understand the Hemi gas V-8 will continue in limited production for the Ram HD.

-

The point is to get away from ICE's. Hybrids still have ICE's. Hybrids, plug-in or otherwise, therefore are not the solution. The recent increase in hybrid interest is driven by current consumer reluctance to buy BEV's and auto manufacturers wanting to recoup ICE costs in danger of eventually becoming 'stranded'. While I believe it is true that many of our elected (and otherwise) officials and environmental advocates are pushing the BEV mandate faster than is technically and economically feasable, it is very clear that BEV's are the long term solution to clean and efficient ground transportation.

-

New Light & Medium Duty News

7Mary3 replied to Joe771476's topic in Ford Motor Company Discussion Forum

Nikola may have started as a scam, but they are making a pretty good go of it now. Jury is still out on hydrogen, but good chance it may eventually replace diesel in long haul trucking. And if it does Nikola will be in a good position: https://www.nikolamotor.com/ -

Yes, but consider this: Would an entry or mid-level manager have the authority to make a major engine design change? I wouldn't think so, but it appears those are the people Farley wants to hold responsible for quality problems. BTW, later FWD versions of the V-6 in question have an external weep hole if the water pump starts to leak. So at least an observant owner can get by with paying a mere $1200 to replace the water pump (probably should do the timing chains, guides, and tensioners while you are at it). Still a stupid design....